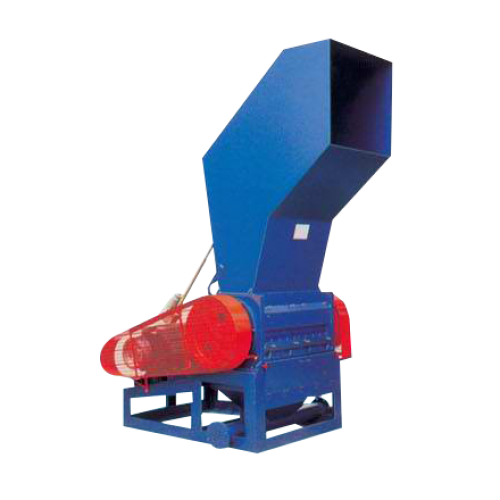

Twin Shaft Shredder

Categories : Plastic Shredders

Design especially for bulky plastic products. Eliminate the disadvantage of traditional high horse power crusher. Also for cracking unusual objects, waste tyres, logs, sleepers, etc. High capacity; low noise; installing easy replaced screen makes the desired output size available The knife is detachable, mutiple used and can minimise the wear and tear cost Easy operation Particle in uniform size Customized size is accepatable

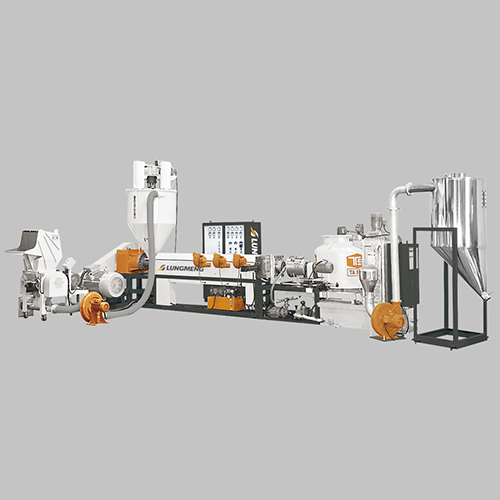

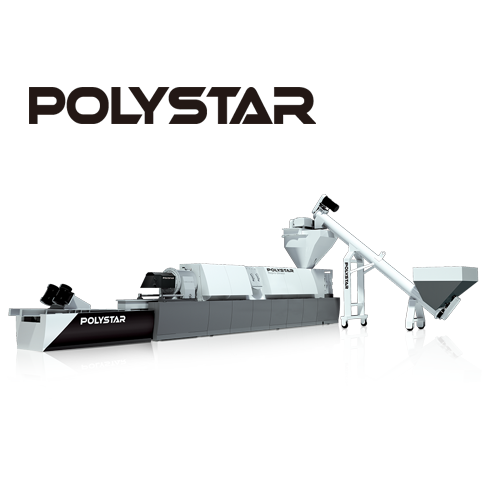

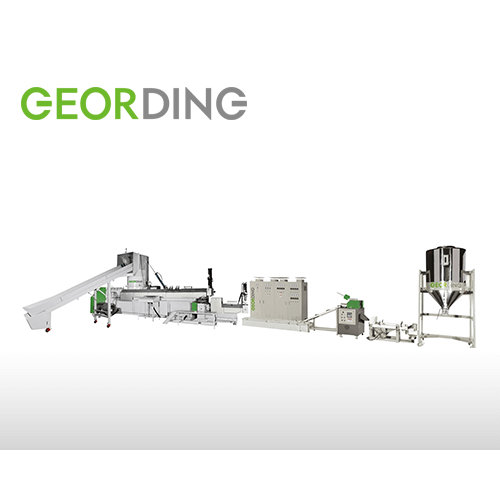

Side Entrance Single Stage Die-Face Type Recycling Machine & Palletizing Machine

Categories : Plastic Waste Recycling Machines

User-friendly machine enables to reach high productivity standards. Product below 7% moisture is suitable for extruding. Applicable to lightweight materials. Crusher is optional. Low labor cost.

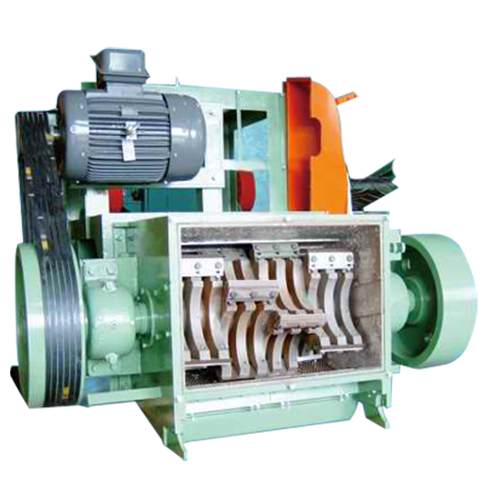

Crushing Machine For Immediate Recycling System - C-200 / 250 / 300 ST

Categories : Plastic Crushers

The plastic crusher is design for plastic manufacturing. Industrial recycling and granulation of plastic. • Suitable materials include plastics such as PP, PVC, PE, PET, ABS, etc. • Applicable fo...

Crushing Machine For Immediate Recycling System C-200 / 250 / 300 SB

Categories : Plastic Crushers

Crushing Machine For Immediate Recycling System C-200 / 250 / 300 SB

Heavy Duty Crushing Machine C300-1000

Categories : Plastic Crushers

Heavy Duty Crushing Machine C300-1000

Low-Speed Crushing Machine - C-S210 / 260 / 310 / 420 SB

Categories : Plastic Crushers

● Slanted tooth rotary cutter for increased cutting power ● Produces little powder and low noise. ● Suitable for materials with high fiber content.

Heavy Duty Crushing Machine C270~1010A

Categories : Granulators

Heavy Duty Crushing Machine C270~1010A

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Categories : Plastic Crushers

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Crushing Machine for Immediate Recycling System C-200/250/300B

Categories : Plastic Crushers

Stainless steel transmission cover

Hopper Feeding Recycling Machine: Repro-Direct

Categories : Plastic Waste Recycling Machines

● The Perfect Solution for recycling plastic films waste/ regrind/ granules ● Crusher and conveyor can be added and combined into a complete recycling line

Plastic Bottles Crusher

Categories : Plastic Crushers

The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. The round and hollow frame structure alows big processing volume. The capacity is 3 times more than the average type crushers. Well-designed angle cutters enables you to properly monitor and run easily the machine making the output estimate for other process. With water cooling system and clearance between cutters makes it easy for heat dissipation that helps reduce damage effect between bearings and machine body. Hardened crusher blades. The adapted ball bearings provide strong friction resistance, good centering and anti-vibration.

Side Entrance Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

Big material storage barrel sustains stability during material input. User-friendly machine enables to reach high productivity standards. Feeding production is more stable than traditional force feeding. Able to open a input hole on top of barrel to conduct feeding formula and master batch pellets. It's a useful and productive type. Crusher is optional. With forced feeding hopper allows the machine to input two kind of material.

Force Feeding Two Stages Die-Face Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing Suitable for a variety of raw materials. Easy to operate; prority transcends traditional model. Low labor cost. Optional equipment- crusher and mixer, enables every batch of material to mix well. Two stages filter makes material more clean

Heavy Duty Crushing Machine - Silent Type C-300STC-560ST

Categories : Plastic Crushers

• Fully enclosed stainless steel casing. • Convenient access doors on five sides. • Dual layer insulation for substantial noise reduction.

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Categories : Plastic Crushers

Low-Speed Crushing Machine C-S210 / 260 / 310 / 420 SB

Low-Speed Silence Crusher (YBCSS)

Categories : Plastic Crushers

This plastic crusher are suitable to granulate a small amount of sprues, waste material or defective products located next to your molding machine. With low-speed and silence design, it can break evenly and...

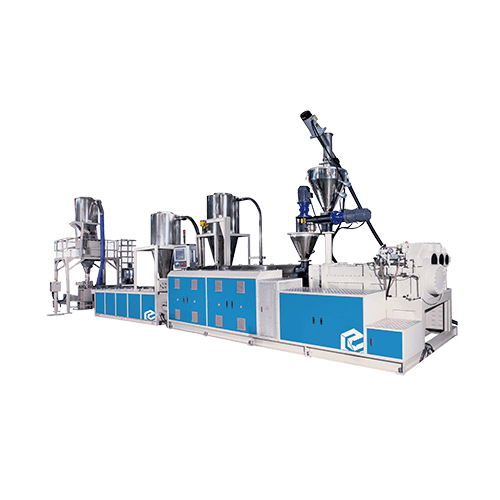

Compounding&pelletizing machine line

Categories : Single Screw Extruders

Everplast provides a complete PVC compound extrusion line, water-cutting pelletizing extrusion equipment, and related peripheral systems such as PVC high-speed mixer system/crusher...etc according to the customer's production demand range. Making the machine easy to operate and stable in production has always been Everplast's goal. For this reason, Everplast has unique designs for the die-face cutting molds and the cooling system so that customers can rest assured and trust the equipment produced by Everplast.

Plastic Crusher for PET Bottles and Other Plastic

Categories : Plastic Crushers

Plastic Crusher for PET Bottles and Other Plastic

Crusher and Storage Plastic Waste Recycling Machine

Categories : Plastic Crushers

Crusher and Storage Plastic Waste Recycling Machine

Plastic Lump Crusher

Categories : Plastic Crushers

Easily maintenance with hydraulic opening body for cleaning residue and changingthe blades. Includes stable energy current system that helps you save energy and with special design on the rotary cutting angle. Bearings have been installed outside of the machine body that enables you to give easy maintenance. The bearings will not be influenced by the temperature of the body, which will increase durability. Hopper is able to take in big plastic products, thanks to the rotating diameter that has been considerably increased. Application- Plastic bottles, plastic tanks, Drums, appliances covers, etc.

Instant Crusher (YBCS)

Categories : Plastic Crushers

An instant recycling system can help you to cost down by recycling the sprues, waste material or defective products. YANN BANG Instant Crusher is also good to granulate long and thick material. The unique safety protection device which is obtained China patent stop completely when abnormal happens. This series is perfect to locate next to a molding machine to recycle immediately.

Crusher (Gepard Series)

Categories : Plastic Crushers

Extremely customizable capabilities Genius provides customizable design plastic crusher for crushing different plastic materials. Equipped numerous types of the optionally input and output system to achieve different demands. The ...

Plastic Crusher, Plastic Scrap Grinding Machine

Categories : Plastic Grinding Machine

This plastic crusher is specially designed for crushing PP/HDPE film, dirty woven bags, used woven bags, PP/HDPE flat yarn to convert into pellets.

Crusher

Categories : Plastic Crushers

Bonmart-Crusher EXTRUDER HEADING MACHINE PRINTING MACHINE CAPPING MACHINE SEALING MACHINE ACCESSORIES

Mighty Crusher (YBC)

Categories : Plastic Crushers

Our crushers are applied to all types of plastic, rubber, resin, and other materials. Large feed inlet can break most kinds of plastic or rubber scrap and waste material easily, bulk feeding more efficient, save labor cost and time. The main structure is made of high quality steel. It is fracture-proof. High-quality blades which increase motor’s efficiencies. With patented design, once the crusher required for maintenance or repair, the crusher will completely stop as the safety device is on and it is very safe for the operator to open the crusher to clean, check or maintain.

Force Feeding Single Stage Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noice; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Spaghetti cutting is suitable for high melting index plastic, Optional equipment- crusher and mixer, enables every batch of material to mix well, No noise during pellet cutting

Instant Recycling System

Categories : Plastic Waste Recycling Machines

In the past, operators throw away the sprues or waste material in small amount or wait for collecting them in big amount to reuse. However, that may be stuck dust by static electricity become too bade to be reused for a while. That not only occupies your space but also costs your time to assort, break plastic nature and regenerate in such long process. Yann Bang “Instant recycling system” use a crusher immediately granulate the sprues, waste material or NG product into small pieces as recycled material that be mixed with virgin material by a proportional valve in right proportion. The recycling process helps you cost down material outlay without effected quality. Small size with low noise and low power consumption is great for long hour operation. A small automatic peripheral instant recycling system for you molding machine combine with four individual equipments: crusher, automatic vacuum loader, hopper dryer and proportional valve. Also can be used with a robot or belt conveyor. The main function is to mix the granulated waste directly from the injection molding machine and the virgin material with a right proportion. Benefit you with less material ware and pollution for your standard productions. 1. Auto instant recycling system can recycle, convey and dry the granulated material sequentially. 2. Less noise and less dust to keep your working area clean. 3. Compact size, light weight and easy-to move. 4. Accurate mixing proportion for good quality. 5. Instant recycling provides the high-efficient productivity and save material cost.

3 IN 1 Two Stages Spaghetti Cutting Recycling & Pelletizing Machine

Categories : Plastic Pelletizer Machines

High torsion, low-noise; temp. controls stability; double degassing, Suitable for a variety of raw materials, Easy to operate; prority transcends traditional model, Low labor cost, Optional equipment- crusher and mixer, enables every batch of material to mix well, Two stages filter makes material more clean

plastic shredder SP-420 / 60205

Especially for bulky plastic products. Eliminate the disadvantages of traditional high horse power crusher.Also for cracking unusual objects,waste tyres,logs,sleepers,etc. ● 2-shaft,claw-cutter breaker has the best ability to shred anything with low noise,vibration free. ● Auto reversible equipment to prolong the life of machine.

Super Power Breaker And Crusher

Categories : Foaming Machinery

For high capacity to cut foam waste into small chips.